Why Membrane Switches Are the Preferred Choice for Compact Devices

The Advantages of Utilizing Membrane Layer Changes in Customer Electronic Devices

Membrane layer switches are increasingly acknowledged for their considerable benefits in customer electronics, particularly in enhancing user interaction and streamlining manufacturing procedures. Their capability to provide intuitive user interfaces and tactile feedback can significantly lower user mistakes, while their lightweight building and streamlined production steps contribute to cost-effectiveness and quicker market access. The versatility in design allows for customized services that satisfy diverse customer demands. The ramifications of these advantages prolong past mere performance, hinting at a transformative possibility for the future of digital gadgets. What further advantages might become this modern technology progresses?

Enhanced Individual Experience

In today's affordable landscape of consumer electronics, improved individual experience is extremely important; nearly 85% of individuals focus on user-friendly interfaces. Membrane layer switches over play a critical function in attaining this level of usability.

The tactile comments provided by membrane switches is vital for assisting individual actions, making certain that commands are registered properly. This comments system enhances and decreases mistakes individual contentment, cultivating a positive connection between the user and the tool. Moreover, the customizable nature of membrane layer changes permits makers to tailor user interfaces to certain user requirements, making devices a lot more available and inviting.

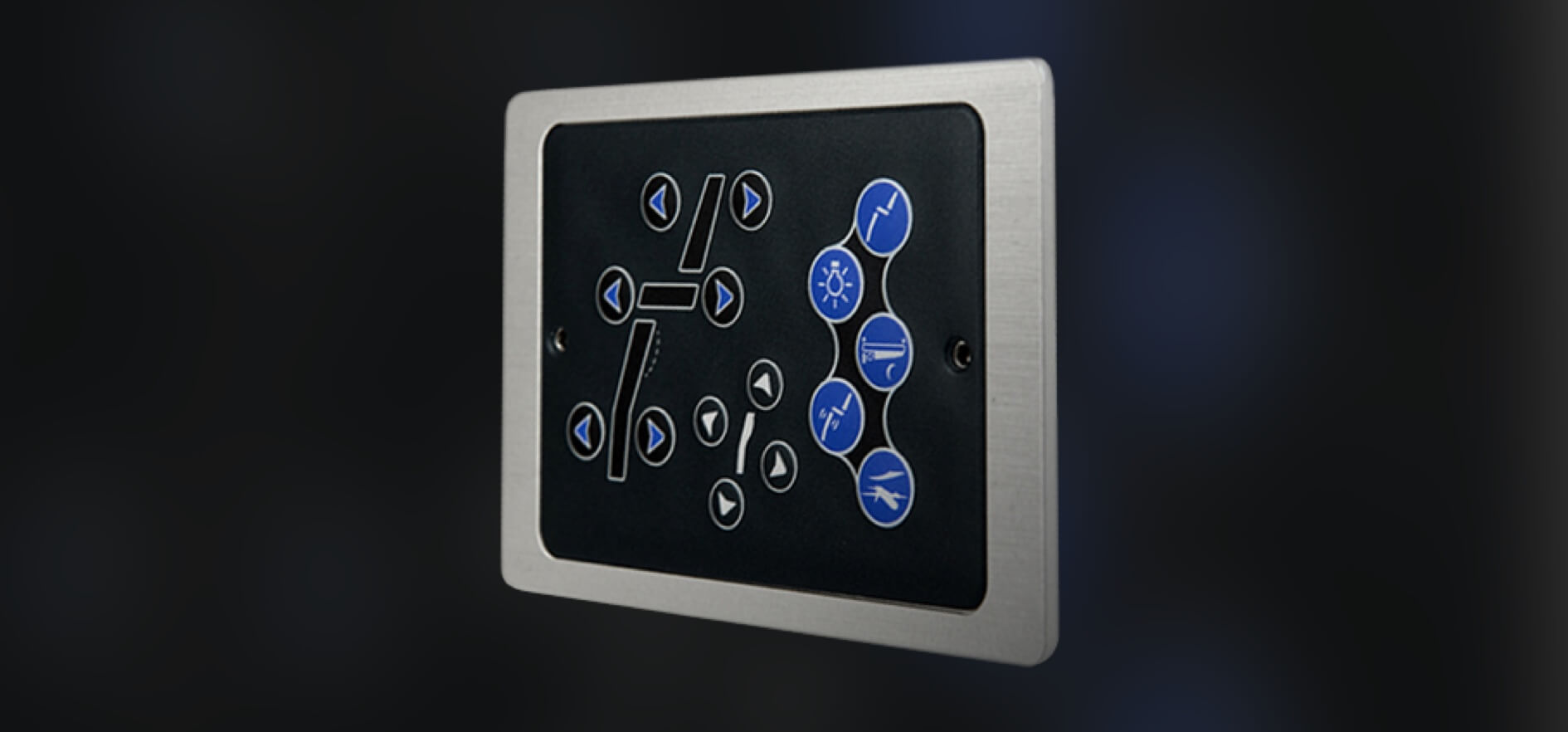

Additionally, membrane layer switches can include backlighting and graphic overlays, even more boosting presence and use in diverse settings. This flexibility guarantees that devices continue to be useful and easy to use, despite the setup. On the whole, the integration of membrane switches right into customer electronics significantly enhances user experience, driving brand commitment and satisfaction in a significantly open market.

Cost-Effective Production

Customer electronic devices suppliers are constantly seeking ways to stabilize high quality with affordability, and membrane layer switches provide a compelling solution for economical production. membrane switch. These components are inherently simpler than standard mechanical switches, which decreases both production costs and intricacy. The light-weight design of membrane changes permits reduced delivery expenses and much easier integration right into compact gadgets, additionally enhancing their appeal in a competitive market

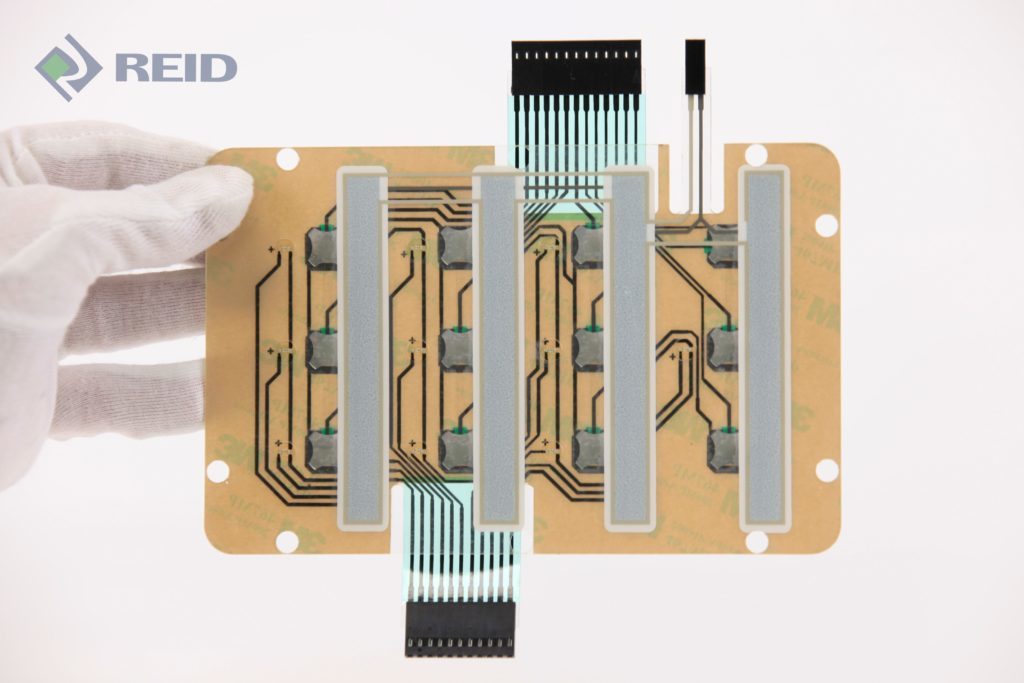

Producers can create membrane layer buttons in high volumes, benefiting from economies of scale. This mass manufacturing capability ensures regular high quality while substantially reducing per-unit prices. Furthermore, the products made use of in membrane buttons, such as polyester and polycarbonate, are typically less costly than those required for conventional switch technologies, adding to overall expense savings.

The production procedure for membrane layer switches normally calls for fewer actions and less labor compared to various other switch types. This streamlined method not just reduces labor costs yet likewise accelerates time-to-market, enabling companies to react promptly to consumer demand. The combination of reduced product expenses and reliable production processes settings membrane layer changes as a smart investment for manufacturers intending to supply premium customer electronics at competitive rate factors.

Design Flexibility and Customization

While conventional mechanical buttons often enforce limitations on style as a result of their bulk and required placing mechanisms, membrane layer buttons give unmatched flexibility and modification alternatives for customer electronics. This cutting-edge technology permits developers to create sleek, low-profile user interfaces that can effortlessly integrate into numerous item appearances, from smartphones to kitchen area devices.

Membrane layer switches can be generated in basically any shape or size, enabling suppliers to tailor the format to certain ergonomic and practical demands. This adaptability not just enhances customer experience however also permits for artistic styles that line up with brand name identification. The usage of printed graphics on membrane switches supplies the opportunity for vivid colors and detailed styles, which can be conveniently changed without significant price implications.

Additionally, membrane layer switches can integrate numerous capabilities into a single layer, lowering the need for multiple components and simplifying setting up processes. This structured style approach lessens room and weight, making it suitable for portable consumer electronics. On the whole, the design adaptability and modification capabilities of membrane changes equip producers to introduce, ultimately causing more interesting and user-friendly items.

Sturdiness and Integrity

As technology remains to evolve, the durability and integrity of membrane switches have actually ended up being essential factors to consider for makers in the customer electronic devices industry. Membrane buttons are designed to hold up against extreme environmental problems, including temperature level variations, dampness, and dust direct exposure. Their durable construction usually entails multi-layered materials that offer an efficient obstacle versus impurities, making certain durability look at this now and consistent efficiency.

Along with environmental resistance, membrane switches deal premium mechanical dependability. Unlike typical mechanical buttons, find out which might wear over time, membrane layer switches over make use of a sealed design that decreases the threat of mechanical failure. The lack of moving parts not just improves their life expectancy yet likewise minimizes wear and tear, making them excellent for high-usage applications.

Additionally, membrane switches can endure a significant number of actuations without loss of performance, typically surpassing countless cycles (membrane switch). This toughness equates to reduce replacement expenses and lowered downtime for consumers and manufacturers alike. Overall, the mix of environmental strength and mechanical reliability makes membrane layer switches a strategic option for consumer electronics, guaranteeing that tools remain reliable and functional throughout their desired life-span

Streamlined Item Development

The sturdiness and reliability of membrane layer switches over dramatically add to structured item advancement in the consumer electronic devices field. By integrating these buttons early in the design process, manufacturers can lower the complexity and variety of elements called for in their products. Membrane layer switches are light-weight and compact, allowing for extra effective area application within tools, which can bring about simplified setting up processes.

The convenience of manufacturing membrane buttons additionally plays a critical duty in product growth. With contemporary printing strategies and products, manufacturing can be scaled efficiently, lessening preparations and minimizing waste. This leads to reduced production expenses, improving general success.

Final Thought

In verdict, membrane layer changes considerably boost customer electronic devices by offering a boosted individual experience, cost-efficient production processes, and functional layout alternatives. The combination of membrane changes represents a tactical selection for manufacturers looking for to enhance item layout and efficiency.

Membrane layer buttons are try this increasingly recognized for their significant benefits in customer electronic devices, particularly in boosting individual interaction and improving production processes. Additionally, the materials made use of in membrane layer switches, such as polyester and polycarbonate, are typically much less pricey than those needed for traditional button technologies, contributing to total cost financial savings.

The manufacturing procedure for membrane layer switches over generally requires fewer actions and much less labor contrasted to other switch kinds. Unlike standard mechanical buttons, which might use out over time, membrane switches over use a sealed layout that lessens the danger of mechanical failing.In conclusion, membrane layer switches significantly boost customer electronics by supplying an improved individual experience, affordable manufacturing processes, and functional style choices.